Project

Motivation

Electric vehicles (EVs) offer significant advantages over conventional internal-combustion engine (ICE) vehicles, particularly in terms of reduced energy consumption and CO2 emissions.

The ShotTempering project

Starting date

01.07. 2024

Duration

42 months

Funded under

RFCS

Funding: 1.18 M€

Challenge

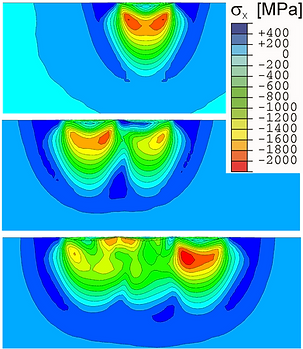

The considerably higher loads experienced by components in EVs compared to ICE-powered vehicles necessitate the development of novel approaches in the production process like shot peening at elevated temperatures to substantially enhance component performance.

Scope and Approach

Unleash the full potenial of warm shot peening:

- to boost the overall efficiency of the process chain in terms of energy consumption, resource utilization, and time savings

- to significantly enhance the mechanical properties of manufactured parts, particularly their fatigue resistance

Impact

-

Reach required component performance that withstand very demanding working conditions typical of today's and future EVs

-

Enhanced competitiveness and cost savings/ increased revenues enabled by novel smart manufacturing processes

-

Increasing environmental sustainability of production processes

-

Strengthening EU’s global technological leadership and first mover advantages